Sample Applications

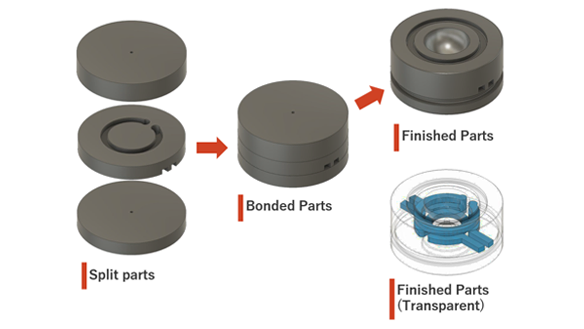

Mold Component for Plastic Bottles (Bottom)

Cycle time during injection molding can be shortened by arranging water channels inside to efficiently cool the molding area.

- Material

- STAVAX

- Size

- Φ60×L30

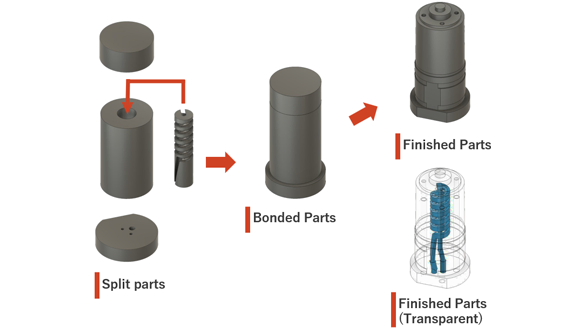

Core Pin for Die Casting Mold

By inserting a part with a spiral groove into a cylindrical part and bonding them together, it is possible to place spiral water inside the product.

- Material

- SKD61

- Size

- Φ40×L80

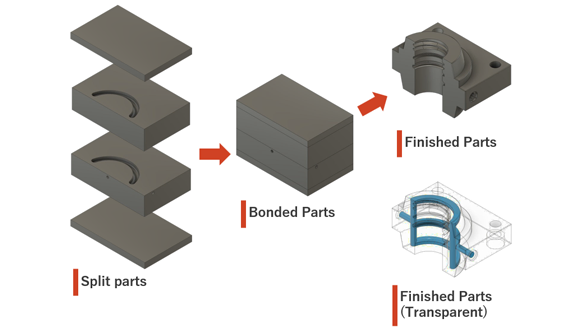

Mold Component for Plastic Bottles (Thread)

Cycle time during injection molding can be shortened by arranging water channels inside to efficiently cool the molding area.

- Material

- STAVAX

- Size

- 64×40×T40

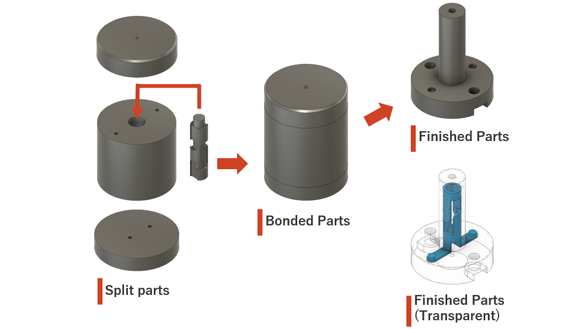

Sprue Bushing

By inserting a part with a spiral groove into a cylindrical part and bonding them together, it is possible to place spiral water inside the product.

- Material

- SKD11

- Size

- Φ40×L50

- (body dia Φ13)

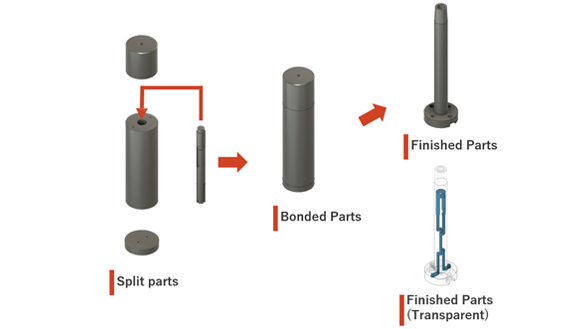

Sprue Bushing (Long type)

By inserting a part with a spiral groove into a cylindrical part and bonding them together, it is possible to place spiral water inside the product.

- Material

- SKD11

- Size

- Φ40×L160

- (body dia Φ16)

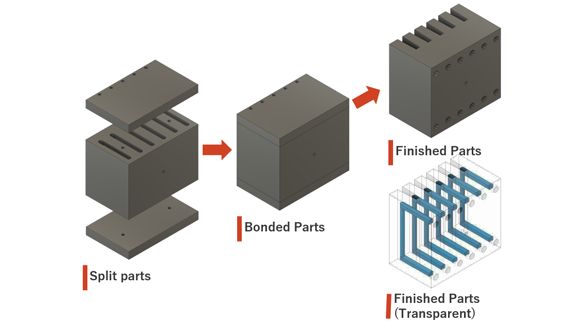

Core for Heat Sink

Internal cooling channels are strategically integrated into fin-shaped components to maximize cooling efficiency and reduce cycle time during injection molding.

- Material

- SKD61

- Size

- 60×65×H80