Supported Part Sizes for P-Bas® Bonding

- Selectable Materials

- Supported Part Sizes for P-Bas® Bonding

- Notes on Dissimilar Materials and Bondable Shapes

Selectable Materials

-

P-Bas® bonding is generally suitable for all steel-based materials.

-

We understand the characteristics of each material and consistently achieve bonding strength that retains over 90% of the base material strength across all material types.

-

Heat and pressure conditions vary depending on the material, so we have been developing bonding conditions suitable for each material.

Bonding Strength Data

You can scroll

| Material | SKD11 | STAVAX | ELMAX | SKD61 | SKH51 | HPM38 | SUS420J2 | SUS440C |

|---|---|---|---|---|---|---|---|---|

| Strength | 101% | 91% | 95% | 98% | 92% | 100% | 100% | 94% |

Hardness

You can scroll

| Material | Heat treatment | Hardness | Tempering temperature |

|---|---|---|---|

| SKD11 | Low temperature tempering | 60~62HRC | 180°C |

| High temperature tempering | 58~60HRC | 530°C | |

| STAVAX | - | 52~54HRC | - |

| ELMAX | - | 58~60HRC | - |

| SKD61 | Heat treatment for Heat | 48~50HRC | - |

| resistance | 50~53HRC | - | |

| Heat treatment for Wear | 59~61HRC | - | |

| resistance | 62~64HRC | - | |

| SKH51 | Heat treatment for toughness | 59~61HRC | - |

| Heat treatment for Wear resistance | 62~64HRC | - | |

| HPM38 | Medium temperature tempering (Non-regular) | 49~53HRC | 350°C |

| High temperature tempering | 52~54HRC | 500°C | |

| SUS420J2 | - | 51~55HRC | - |

| SUS440C | Low temperature tempering | 56~58HRC | 180°C |

| High temperature tempering | 52~55HRC | 500°C |

Supported Part Sizes for P-Bas® Bonding

-

P-Bas® bonding can be applied to components with dimensions of up to 120 mm in diameter, 140 mm in height, and a total volume of 350,000 mm3 or less.

-

The recommended size is approximately the size of the palm of the hand. As long as the part fits within the bonding equipment, multiple components can be bonded simultaneously in a single cycle.

Bonding strength data

You can scroll

| Size[mm] | 110×110×T60 | 51×61×T160 | 47×107×T66 | 47×107×T46 | Φ40×T80 | Φ60×T30 |

|---|---|---|---|---|---|---|

| Volume[mm3] | 726,000 | 497,760 | 331,914 | 231,334 | 100,480 | 84,780 |

Notes on Dissimilar Materials and Bondable Shapes

Bonding Dissimilar Materials

-

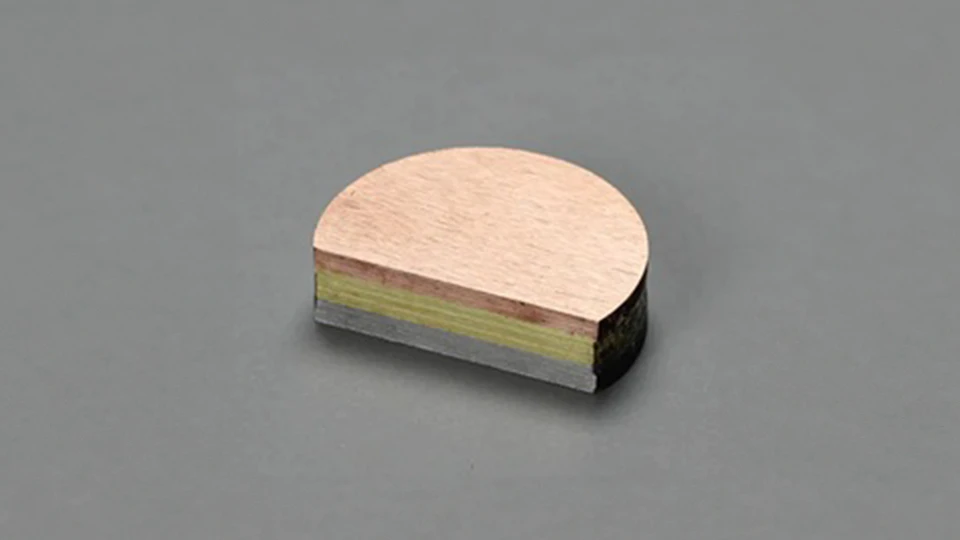

P-Bas® also supports the bonding of dissimilar materials.

-

By combining standard mold and die materials with materials that offer high thermal conductivity or non-magnetic properties, material costs can be reduced.

Bonding dissimilar materials

Materials : Copper + Brass + Iron

Materials : Copper + Brass + Iron

Bondable Shapes

-

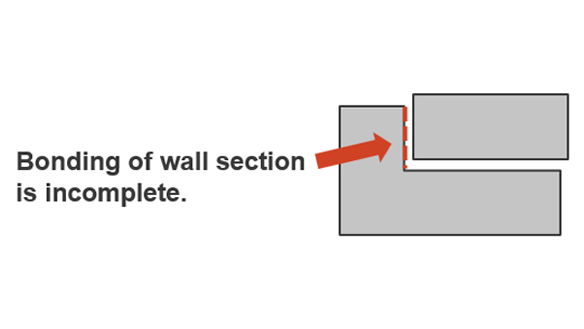

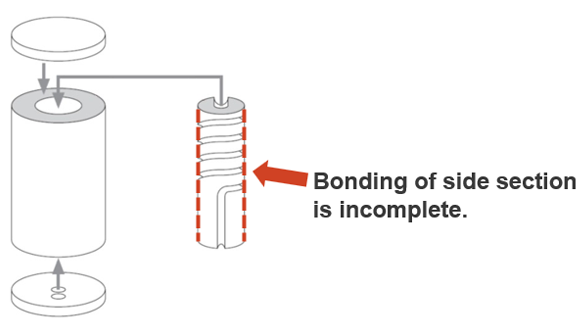

Flat joints are the basic type of joint.

-

In a joint where a cooling channel is inserted into a cylinder, only the flat surface of the lid will be properly bonded; incomplete bonding will result on the sidewalls.

-

Similarly, when bonding parts with steps or uneven surfaces, vertical areas may not achieve full bonding.

Product with a spiral channel

Staircase-shaped product