About Punch Group

Our Purpose

Sincerity in Technology and Free Creative Power

Thoughts included in the Purpose

The mission of the Punch Group is to enrich the world with trust, technology and flexible creativity cultivated through our commitment and sincere efforts to manufacturing.

Our starting point was the development and mass production of the world's first high-speed steel ejector pins for plastic molds. What supported us in overcoming this difficult challenge was our passionate desire to support our customers' success and bring them joy.

This passion has been passed down as our corporate identity embodied in the Punch Spirit of "Challenge," "Imaginative & Innovative" and "Open & Honest." Based on these ideas, we have a desire to support the realization of a better society through manufacturing, and while taking on the challenge of technological innovation and improvements in quality, we have continued to grow together with our customers and partner factories around the world. In addition, as demonstrated by our efforts as an industry leader in environmentally friendly manufacturing and other measures, we have always focused on social issues and worked sincerely to address them.

Going forward, through manufacturing and creativity with "Punch," as well as with the technical capabilities and solutions to make those possible, we will strive to make the dreams of society come true. Moreover, like the mold and die components that served as the cornerstone of our founding and are built into the molds and dies that give shape to products, we will help shape a future that does not yet exist and expand the possibilities of the world.

Promises of the Punch Group

While supporting everyday life, we will contribute to the sustainable development of society by continuing to meet the needs around the world through the creation of new value.

In addition, through our efforts to minimize environmental impacts and through our social contribution activities, we will pass on an even better Earth to the next generation.

To realize this, we will maintain close relationships and move forward together with all stakeholders, and continue to be a company that takes pride in providing value to society.

-

To our customers

We will support growth utilizing the manufacturing solutions of the Punch Group. We will always provide our customers with value that exceeds their expectations.

-

To our employees

We will provide an environment in which employees can work with pride, and support the growth and self-realization of each and every employee.

-

To society

We will respond to changes in the natural environment and society, which will lead to an even better future for the next generation.

Management Principle

Driven by the spirit of challenge, we will continue to develop and propose advanced technologies in response to customer needs, for the benefit of society.

We will create a vibrant corporate culture (workplace) that fulfills people's dreams, by placing high value on vigorous energy and flexible ideas.

We will contribute to social development by embracing the spirit of environmental consideration and compliance and promoting sound corporate activities that are appreciated by society.

Corporate Motto

Long-term Vision

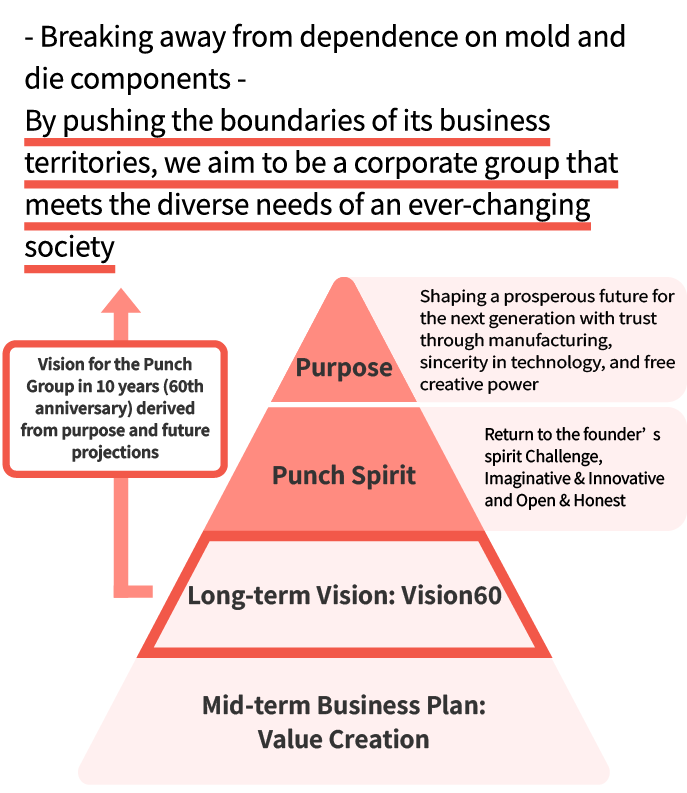

In May 2025, the Punch Group formulated its first long-term vision, Vision60. Marking our 50th anniversary in March 2025, this vision looks ahead to our 60th anniversary, envisioning the Punch Group's "ideal state" in ten years, outlining the strategy that will lead us there across our next three mid-term business plans.

Under the banner of "breaking away from dependence on mold and die components" to reach our ideal state in 10 years, the Group will continue to push the boundaries of its business territories while striving to meet the diverse needs of an ever-changing society.

By pushing the boundaries of its business territories, we aim to be a corporate group that meets the diverse needs of an ever-changing society

The Punch Group is a manufacturer and seller of parts for mold and die, established in 1975.

Under our Purpose--"Shaping a prosperous future for the next generation with trust through manufacturing, sincerity in technology, and free creative power"--as a statement to reaffirm the Group's reason for existence, we have kept our commitment to quality manufacturing since our founding, and have made steady progress in building up a comprehensive production system, from materials procurement all the way to shipment.

In March 2025, we welcomed our 50th anniversary and are looking ahead to the next decade, we formulated our long-term vision, Vision60. Under this vision, we set forth our aspiration of "breaking away from dependence on mold and die components." On the basis of this policy, the Punch Group aims to push the boundaries of its business territories and be a corporate group that meets the diverse needs of an ever-changing society.

And, to promote those initiatives, we have a concept named "Punch Spirit", which represents our thoughts of returning to the spirit of our founder and a honorary chairman, Yuji Morikubo. With keywords "Challenge", "Imaginative & Innovative" and "Open & Honest", we will strive to achieve our target and will try our very best to further contribute to "global craftsmanship" in the industry.

At the same time, we will continue our effort to further improve transparency and sound management, and promote corporate activities that earn the adoration of society, so as to meet the expectations of all our stakeholders.

We look forward to your continued warm support of our efforts.

Tetsuji Morikubo, President and CEO

- Punch Group in Numbers

- Punch Group products used in Society

- What are Mold and Die Components?

- Strengths of the Punch Group

- Company introduction video

Punch Group in Numbers

-

Establishment1975

-

Number of employees3,463(March 2025)

-

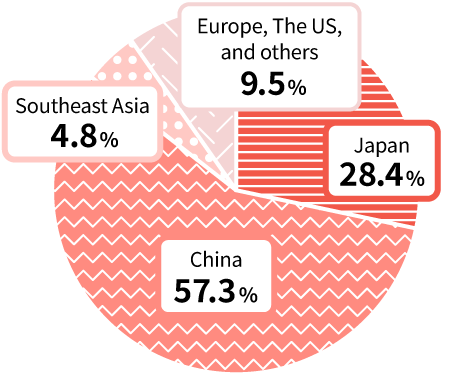

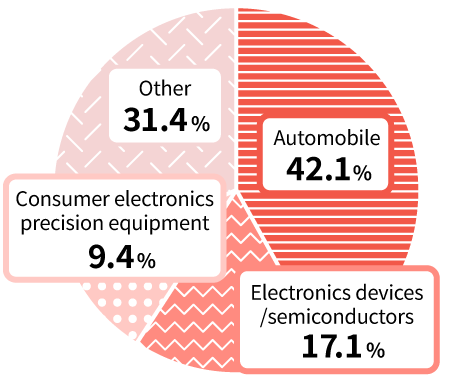

Composition of Sales by Region and by Industry (March 2025)Composition of Sales by Region

Composition of Sales by Industry

Composition of Sales by Industry

-

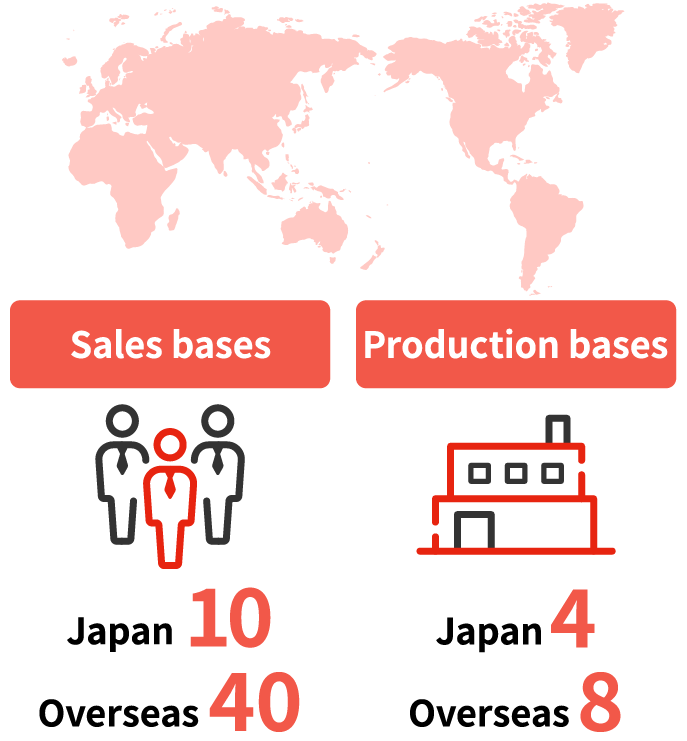

Number of locations:

Punch Group products sold in over 40 countries worldwide

Punch Group products used in Society

- At office

- Aerospace Industry

- At hospital

- At supermarket

- Automobile

- Daily necessities・Interior goods

- At factory

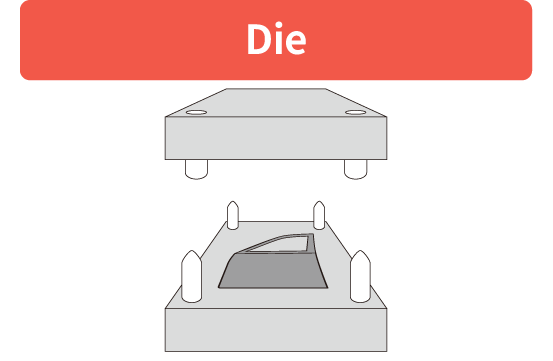

What are Mold and Die Components?

Indispensable Presences for Molds and Dies, Supporting Manufacturing Worldwide

The Punch Group is a leading global manufacturer of precision mold and die components.

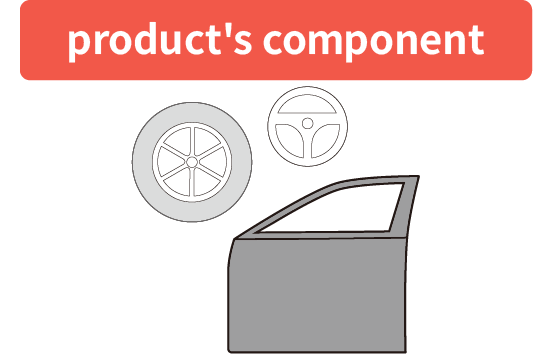

Molds are tools used to produce large quantities of products with consistent quality and speed. Of the countless products found throughout society, such as automobiles, electronic devices, and home appliances, few are made without the use of molds.

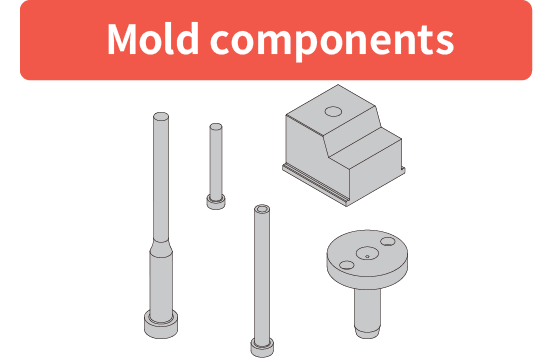

We manufacture a wide variety of mold and die components that are indispensable to those molds. Our components support manufacturing operations around the world in a wide range of sectors, including automotive, electronics and semiconductors, food packaging, medical, and aerospace.

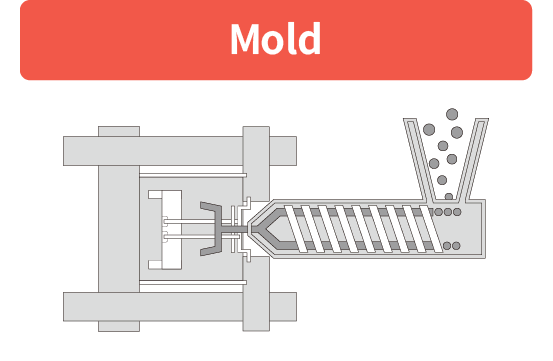

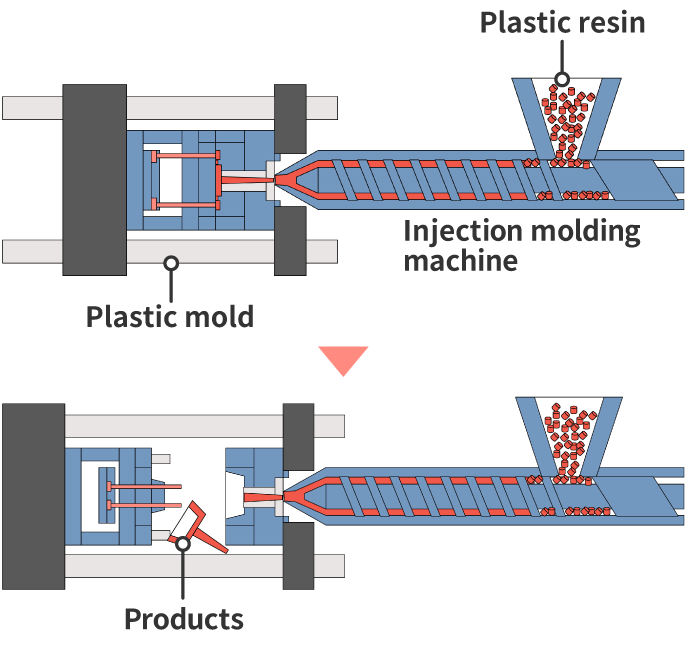

How Plastic Molds Work

Plastic molds are used to manufacture plastic products. Plastic resin is heated and melted, then injected into a mold set into an injection molding machine. It is then left to cool and solidify, forming the plastic part.

-

A: Mold components are set into the mold

-

B: Heated and melted plastic resin is injected into the mold installed in an injection molding machine

-

C: The resin is cooled to form a product's component

-

D: The components are assembled to complete the product

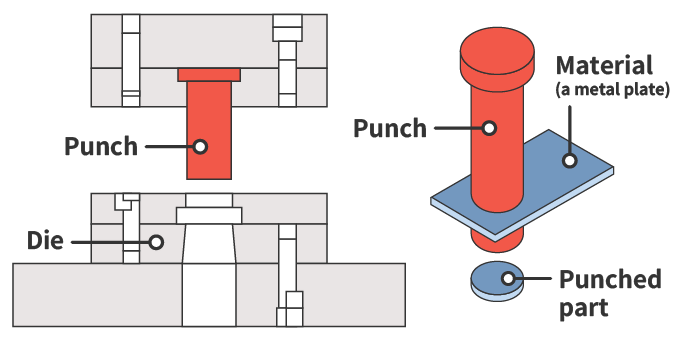

How Press Molds Work

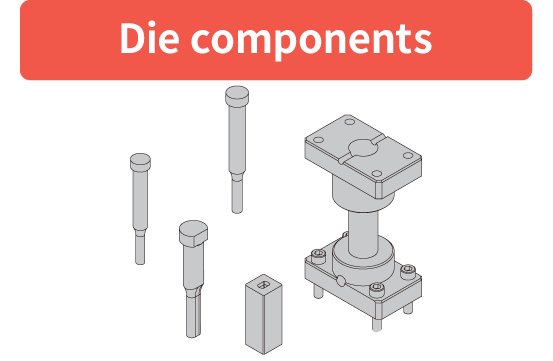

A press mold is set into a press machine, which operates with an up-and-down motion. Material (a metal plate) is placed between the upper and lower halves (punch and die) of the mold. The machine applies pressure to the die to bend or punch the material.

-

A: Mold components are set into the mold

-

B: The mold is inserted into the press machine, and a metal sheet is placed between the upper and lower halves of the mold

-

C: The press machine applies pressure to punch the metal plate, forming a product component

-

D: The components are assembled to complete the product

Strengths of the Punch Group

-

Capable of processing a wide variety of made-to-order products

We are the world leader in the market for custom-made mold-die parts, manufactured precisely according to customer drawings (based on our estimates). We supply high-quality mold and die components to over 15,000 customers in more than 50 countries around the world.

-

World-class lineup of metal processing equipment

We operate over 2,000 units of machining equipment across our product sites. Since our founding in 1975, we have built an all-inclusive production system that combines our precision machining expertise with the latest machine tools and measuring equipment, allowing us to deliver quality, speed, and cost advantages to our customers.

-

Extensive lineup of standard parts

We also offer a wide range of high-quality standard parts with broad versatility, helping our customers boost their productivity while keeping costs down.

-

Serving a wide range of industries and regions

We work with customers across a broad spectrum of manufacturing sectors, including automotive, electronics and semiconductors, food packaging, medical, and aerospace. We address myriad customer challenges by applying expertise across multiple fields from a wide range of industries.

We also have facilities in multiple countries that allow us to supply high-quality products to customers at their international locations.