Advantages of P-Bas

Comparison with metal 3D printers

You can scroll

| Metal 3D printer | P-Bas® Bonding | |

|---|---|---|

| Cost/Production Time | 15-30 hours + 2 hours for finishing (depending on the capacity of the equipment) | 4 hours + 2 hours for finishing (2 hours for water pipe processing, 2 hours for joining) |

| Cost/Material costs | 10,000-15,000 yen (unit price: 20,000 yen/kg) | 1,700 yen (unit price: 2,000 yen/kg) |

| strength | Inferior to general special steel* | With the strength of special steel |

| Material | Mainly maraging steel | All types of special steel are available. |

*

Metal 3D printers melt powder and solidify it, which generally results in lower strength compared to conventional materials that are forged and rolled.

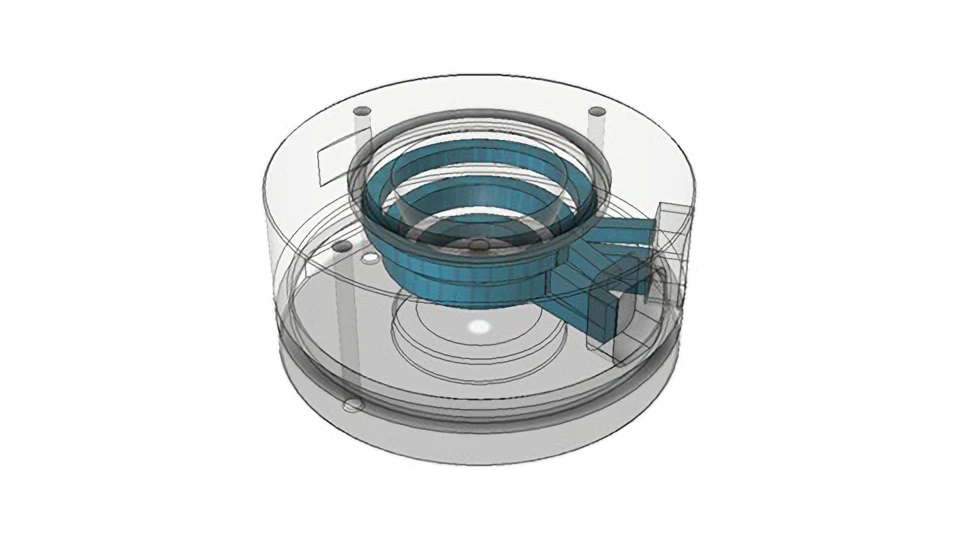

Mold Component for Plastic Bottles

Size : φ60 X L30

Weight : 650g

Size : φ60 X L30

Weight : 650g

Cooling channel rust prevention

Comparison with metal 3D printers

- Metal 3D Printing:

- Since components are formed by layering metal powder, the internal cooling channels have a rough surface finish.

- Prone to rust formation.

- P-Bas® Bonding:

- Because cooling channels are finished by precision machining, the surface finish of the cooling channel is finer.

- A protective coating can be applied to the inside of the cooling channel for more effective rust prevention.

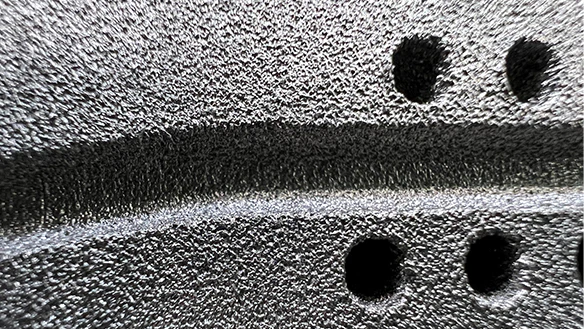

Rust of Metal 3D Printer Product

Water pipes processed by metal 3D printers have a rough surface because they are made by melting and solidifying metal powder.

In contrast, P-Bas creates water pipes through machining. This results in a smooth surface that is resistant to rust.

Surface Roughness of Metal 3D Printer Product

Surface Roughness of P-Bas Product

Bonding after surface coating

Surface treatment for cooling channels (patent pending) to protect against rust

-

A surface coating is applied to the channels of the split parts before bonding to further suppress rust formation.

-

Since heat is applied to the parts during and after bonding, we use a rust-preventing coating that can withstand high temperatures.

Bonding after surface coating