Special order parts

- Why Customers Choose Punch

- Available Materials

- Equipment List

- Heat Treatment Conditions

- Examples of Special Order Products

- Process from Quotation to Delivery

Why Customers Choose Punch

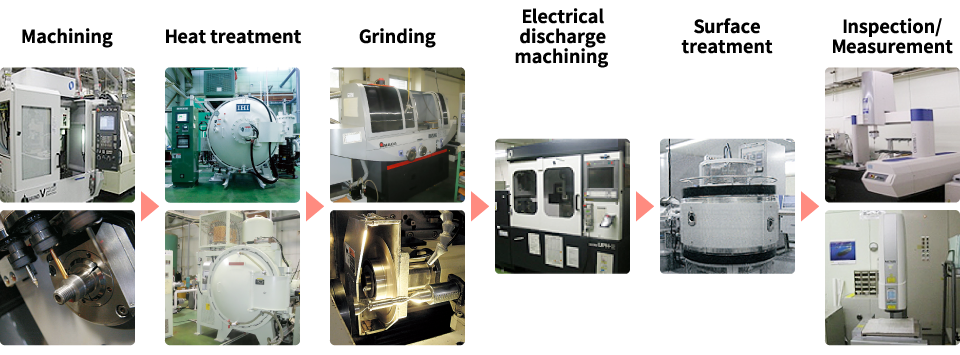

We also handle secondary processes, such as surface treatment, within our all-inclusive production system. Drawing on over 50 years of expertise in precision machining, we accurately translate our customers' requirements into forms that best suit their needs.

Available Materials

Other materials not listed here are also available. Please contact us to discuss your specific requirements.

Metal materials

You can scroll

| Category | Material |

|---|---|

| Steel for plastic molds | NAK55, NAK80, PD613, YAG300, HPM1, HPM31, HPM38, HPM75, ELMAX, STAVAX, M390, MOLDMAX |

| Cold working mold steel | HAP10, HAP40, HAP72, HAP50, HAP5R, SLD, YXR3, YXR33, YXR7, DC53, DEX20, DC11, SKD11, SX105V, ASP60, ASP30 |

| For hot working molds | SKD61 |

| High-speed tool steel | SKH51, SKH55, SKH57, SKH51, HM-1, YXM60, DRM2 |

| Carbon Structural Steel | S45C |

| Alloy tool steel | FDAC, SKS2, SKS21, RIGOR, SKS21H, GO4, GOA |

| Stainless steel | SUS303, SUS304, SUS440C, SUS420J2, SUS440C |

| Carbide | MG30HIP, CTS20D, MG30HIP, CTS20D, CF-H40S |

| Carbon tool steel | SK4 |

| Chrome molybdenum steel | SCM415, SCM435 |

| Copper alloy | CU1100, BsBm, BECU25 |

| Spring steel | SUP9 |

| High-carbon chromium bearing steel | SUJ2 |

| High specific gravity composite alloy | HV28 |

| Aluminum alloy | A5052 |

Resin material

You can scroll

| Category | Material |

|---|---|

| Thermosetting resin | Paper Bakelite, cloth Bakelite, glass epoxy, glass silicon, etc. |

| Thermoplastic resin | Polyvinyl chloride, acrylic, polycarbonate, polyethylene, polypropylene, MC nylon, ultra-high molecular weight polyethylene, ABS, PEEK, etc. |

| Ceramic | Heat resistant (various types from 100°C to 1000°C) |

| Other | Fiber Reinforced Plastics, Rubber, etc. |

Equipment List

You can scroll

| Category | Equipment name | Main Features | PCS |

|---|---|---|---|

| Cutting machines | CNC lathe | Multi-tasking CNC lathe, with automatic material supply device | 643 |

| Machining center | 5-axis Multi-tasking machine etc | ||

| Other cutting machine | Milling machine, gun drill machine, engraving machines etc | ||

| Grinding machines | Forming and Surface Grinding Machine | CNC precision form grinding machine etc | 1,076 |

| CNC centerless grinder | Ultra-high precision etc | ||

| CNC cylindrical grinder | CNC, Punch grinding machine etc | ||

| CNC profile grinder | CNC, High-precision specification etc | ||

| CNC DedTru grinder | CNC etc | ||

| CNC internal surface grinder | CNC, Small-diameter high-speed specification etc | ||

| Other grinder | Jig grinding machine, high-precision CNC tool grinding machine | ||

| Electrical discharge machines | CNC die sinking electrical discharge machine | Ultra-precision CNC die-Sinking EDM machine etc | 208 |

| CNC wire electrical discharge machine | High-speed, high-precision specification etc | ||

| Heat treatment facilities | Vacuum heat treatment furnace | Tempering, oil quenching, high-frequency hardening subzero treatment equipment etc |

87 |

| Surface treatment equipments | PVD equipment | PVD, radical nitriding, hard chrome plating etc | 17 |

| Others | - | Laser marking machine etc | 48 |

| Inspection and measuring instruments | - | Surface roughness and contour profilometers, image processing systems, X-ray fluorescence analyzers, 3D scanners etc | 901 |

Heat Treatment Conditions

We provide heat treatment services.

For materials, hardness levels, or treatments not listed in the brochure, please contact us.

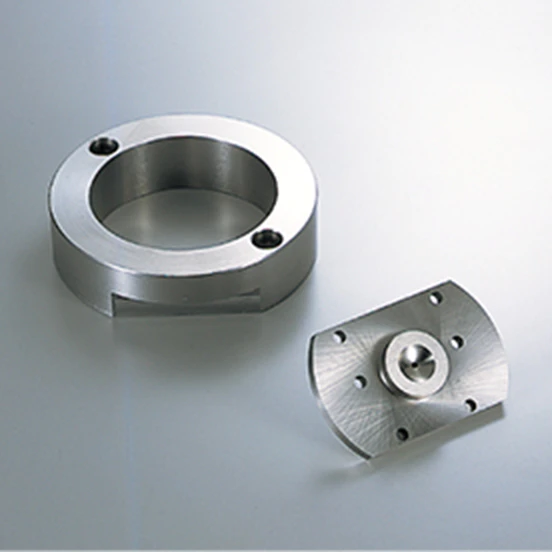

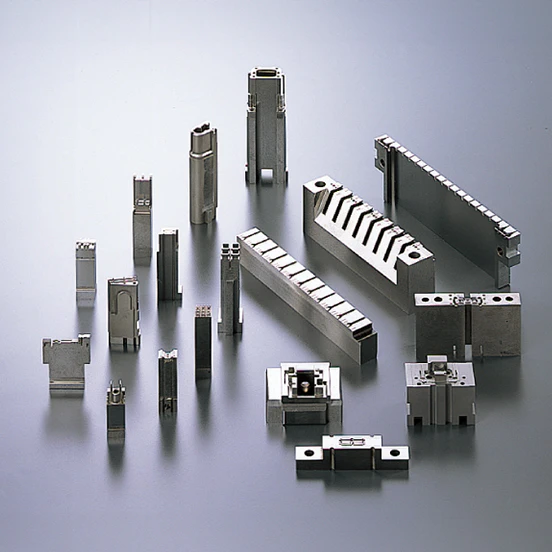

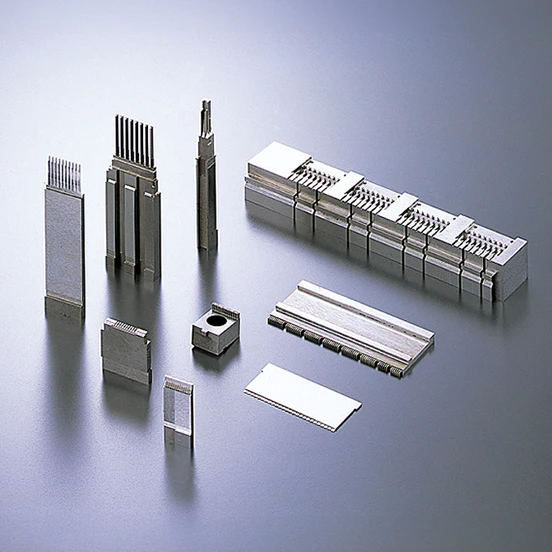

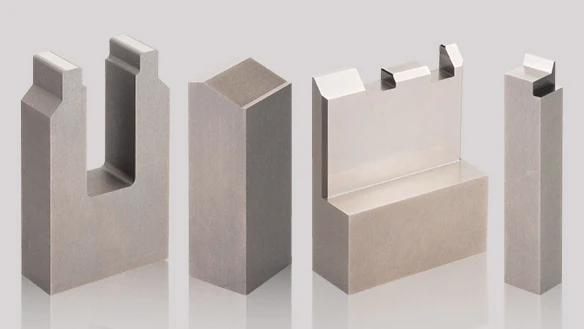

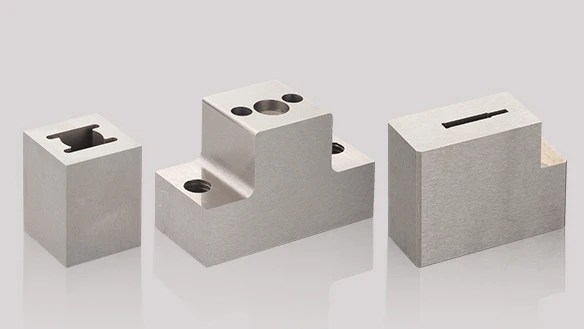

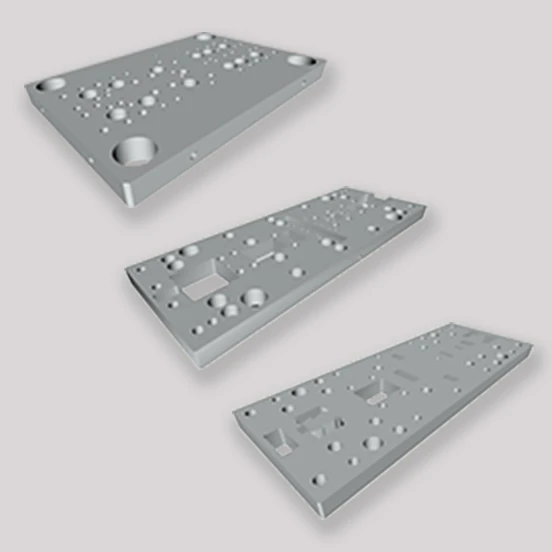

Examples of Special Order Products

Catalog products in custom sizes

We fabricate parts in extra-large or small sizes based on standard parts from our catalog, including round or square ejector pins, sleeve pins, and punches and dies.

Made-to-order parts

We also excel in fabricating made-to-order parts to meet unique specifications based on customer drawings. We accept orders from one piece to hundreds of pieces.

Key points:

-

The Group has over 2,000 precision machining units, such as cutting and grinding machines, along with a wide array of measurement equipment.

-

Along with steel and aluminum, we also specialize in processing carbides and other tough-to-process machining materials.

We also offer various coatings and surface treatments!

We fully meet needs for customer-requested functions by way of an all-inclusive crafting system that besides guaranteeing dimensional accuracy, also performs surface processing and heat treating, etc.

Key points:

-

Punch Industry provides a nimble yet meticulous response to wide-ranging customer needs such as for slidability, high strength, and wear-resistance.

Our all-inclusive production-crafting system delivers unique benefits!

Our end-to-end production system encompasses every stage from material procurement to heat treatment, machining, surface processing, inspections, and measurement, all within a single integrated system. This approach allows us to deliver outstanding quality, reliable lead times, and competitive pricing.

Process from Quotation to Delivery

-

(1)Request for Quotation

-

(2)Order Request

-

(3)Product Processing

-

(4)Inspection

-

(5)Product Shipment

-

(6)Delivery to Customer